Description

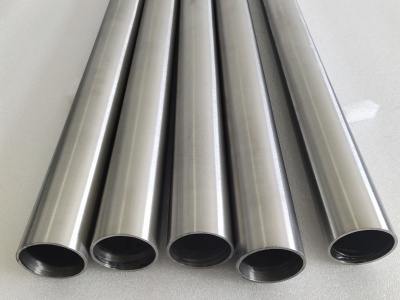

1. Introduction to Tantalum Tube

- Grade number: RO5200, RO5400

- Specifications: Diameter: 0~150mm, Wall thickness: 0.1~5mm, Length: 10mm~6000mm

- Delivery status: Cold rolled glossy surface (hard state, annealed state)

- Form: straight pipe, coil pipe

- Purity: ≥95%, 99.99%

- Standard: ASTM B521, GB/T8182

- Cold rolling, pickling, shearing

- Density: 16.67g/cm3

- Melting point: 2996℃

2. Application fields of Tantalum Tube

Tantalum tube Tantalum tube High-purity tantalum tube thick-wall tantalum tube application: used for heat exchanger in the acid production industry, protective pipes and pipelines in the chemical industry, etc.

Third, chemical ingredients

<td<td<td<td<td<td

| Ingredients (%) | |||||||||||||

| Brand number | Main ingredients | Impurity content (≤) | |||||||||||

| Facing | Nb | Fe | And | In | W | Mo | Of | Nb | O | C | H | N | |

| Ta1 | Remaining | — | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.005 |

| TA2 | Remaining | — | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.005 |

| Tanb3 | Remaining | 1.5~3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | — | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb20 | Remaining | 17.0~23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | — | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb40 | Remaining | 35.0~42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | — | 0.02 | 0.01 | 0.015 | 0.01 |

| TA2.5W | Remaining | — | 0.01 | 0.005 | 0.01 | 2.0~3.5 | 0.01 | 0.002 | 0.1 | 0.01 | 0.01 | 0.0015 | 0.01 |

| Ta10W | Remaining | — | 0.01 | 0.005 | 0.01 | 9.0~11.0 | 0 | ||||||

4. Mechanical properties:

| Brand number | Minimum tensile strength (MPa) | Minimum yield strength (MPa) | Elongation, minimum, % (25.4mm gauge distance) |

| RO5200 , RO5400 | 207 | 138 | 25 |

| Ro5252 | 276 | 193 | 20 |

| Ro5255 | 481 | 414 | 15 |

| RO5240 | 276 | 193 | 20 |

Tolerance of outer diameter and wall thickness of tantalum tube (mm):

| Outer diameter | Outer diameter tolerance | Wall thickness tolerance |

| 1~20 | 0.01 | ±5% |

| 20~25 | 0.05 | ±5% |

| 25~40 | 0.10 | ±5% |

| 40~60 | 0.15 | ±5% |

| 60~80 | 0.20 | ±5% |

| 80~150 | 0.25 | ±5% |