Description

Scope of supply of Aviation Group:

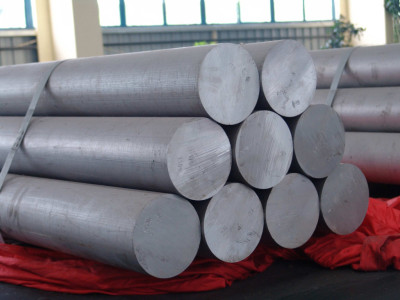

It can be customized non-standard, aluminum plate (whole plate/cut), aluminum rod, aluminum forgings, aluminum tubes, aluminum profiles, etc. Welcome to inquire!

1. Introduction to 7050 Materials

7075 aluminum alloy is a cold-treated forged alloy with high strength, far better than mild steel. 7075 is one of the most powerful alloys used in commercial use. After heat treatment, it can achieve very high strength characteristics. The 7075 material is generally added with a small amount of copper, chromium and other alloys. Among the series, 7075-T651 aluminum alloy is particularly top-notch. It is known as the best product among aluminum alloys, with high strength and far superior to any mild steel. This alloy has good mechanical properties and anode reaction.

7075 mainly contains zinc. It also belongs to the aviation series, is an aluminum-magnesium-zinc-copper alloy, a heat-treated alloy, and has good wear resistance. The 7075 aluminum plate is stress-free and will not deform or warp after processing. All the super-large and super-thick 7075 aluminum plates are detected by ultrasonic waves, which can ensure that there is no sand holes and impurities. The 7075 aluminum plate has high thermal conductivity, which can shorten the forming time and improve working efficiency. The main feature is that the high hardness 7075 is a high hardness and high strength aluminum alloy, which is often used to manufacture aircraft structures and futures. It requires high-stress structural parts and mold manufacturing with high strength and corrosion resistance.

2, 7075 Chemical Ingredients

| Alloy Medal | silicon

And |

iron

Fe |

copper

Cu |

manganese

Mn |

magnesium

Mg |

chromium

Cr |

Zinc

Zn |

titanium

Of |

other | aluminum

AL |

||

| New grade | Old brand | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | Each | total | margin |

| 7075 | – | 0.05 | 0.15 | |||||||||

3. 7075 physical properties and characteristics

| Aluminum alloy grade and status | tensile strength

Rm/Mpa |

Yield of yield

Rp0.2/Mpa |

Elongation/% | Hardness/HBWα | density

(20 ℃) (g / cm3) |

| 7075-T6 | 572 | 503 | 11 | 150 | 2.9 |

7075 aluminum alloy features

1. High-strength heat-treated alloy.

2. Good mechanical properties.

3. Good usability.

4. Easy to process and good wear resistance.

5.T7351 state enhances corrosion resistance

6. High-strength materials used in high-pressure structural parts.

The 7075 material is generally added with a small amount of copper, chromium and other alloys. Among them, A7075-aluminum alloy is particularly best. It is known as the best product among aluminum alloys, with high strength and far superior to any mild steel. This alloy has good mechanical properties and anode reaction.

IV. 7075 application fields

7075 is suitable for aerospace industry, blow molding (bottle) molds, ultrasonic plastic welding molds, golf ball heads, shoe molds, paper molds, foam molds, wax removal molds, templates, fixtures, machinery and equipment, mold processing, and is used to make high-end aluminum alloy bicycle frames, etc. Representative uses include aerospace, mold processing, mechanical equipment, tooling and fixtures, especially for the manufacture of aircraft structures and other high-stress structures with high strength and corrosion resistance.