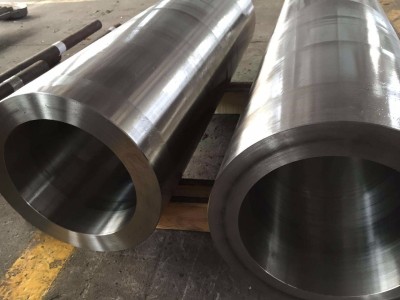

Description

Scope of supply of Aviation Group:

Round rods, steel plates, non-standard forgings, rings, etc., welcome to inquire!

1. Introduction to W6Mo5Cr4V2 materials

W6Mo5Cr4V2 high-speed tool steel is abbreviated as high-tech steel or high-speed steel, commonly known as “front steel” or “wind steel”. It is a high-carbon and high-alloy tool steel suitable for high-speed cutting.

Due to resource and price relationship, many countries have replaced W18Cr4V with W6Mo5Cr4V2 steel and have become the main steel number for high-speed steel. W6Mo5Cr4V2 high-speed steel has excellent toughness, wear resistance and thermoplasticity, while its hardness, red hardness and high temperature hardness are comparable to W18Cr4V. Therefore, in addition to being used to manufacture various types of general tools, W6Mo5Cr4V2 high-speed steel can also make large and thermoplastic tools. Because W6Mo5Cr4V2 steel has high strength and good wear resistance, it can also produce wear-resistant parts under high loads, such as cold extrusion molds, but at this time, the quenching temperature must be appropriately lowered to meet the requirements of strength and toughness. W6Mo5Cr4V2 high-speed steel is easy to oxidize and decarbonize, and attention should be paid during thermal processing and heat treatment.

2. Chemical composition of W6Mo5Cr4V2

| alloy | % | Chromium Cr | Stone Mo | Tungsten W | Vanadium V | Carbon C | Manganese Mn | Silicon Si | Phosphorus P | Sulfur S | Ni | 铜 with |

| W6Mo5Cr4V2 | Minimum value | 3.8 | 4.5 | 5.5 | 1.75 | 0.8 | 0.15 | 0.2 | – | – | – | – |

| Maximum value | 4.4 | 5.5 | 6.75 | 2.2 | 0.9 | 0.4 | 0.45 | 0.03 | 0.03 | 0.03 | 0.25 |

3. Physical performance of W6Mo5Cr4V2

Delivery hardness: (other processing methods) ≤262HB; (annealing) ≤255HB. Thermal treatment system and quenching hardness: ≥63HRC (box furnace), ≥64HRC (salt bath furnace)

The density of W6Mo5Cr4V2 steel is 8.16t/m3; the elastic modulus E is 218,000MPa.

4. W6Mo5Cr4V2 material characteristics

W6Mo5Cr4V2 steel is abbreviated as W6 or 6542, and is the representative steel number of the tungsten-molybdenum-based general-purpose high-speed steel. It is a high alloy steel containing a variety of alloy elements and belongs to the Leninite type steel type. It has high hardness, high wear resistance, high heat hardness, high hardenability, sufficient plasticity and toughness, and has good casting, forging, welding and mechanical processing properties. Therefore, it occupies and has an important position in tool steel.

V. W6Mo5Cr4V2 heat treatment process

Quenching temperature: (salt furnace 1210~1230, box furnace 1210~1230); quenching: oil; tempering temperature 540~560 degrees Celsius; HRC (box furnace 63, salt bath furnace 64).

Delivery status: Hot-rolled, forged, and cold-pulled steel rods are delivered in annealed state, and hot-rolled and forged steel rods are delivered in annealed + other processing methods (skinning, light pulling, polishing or polishing, etc.).

Quenching specifications:

Table 2-26-1 Recommended quenching specifications for W6Mo5Cr4V2 steel

| Tool Type | Preheating temperature/℃ | Heating temperature/℃ | Termination temperature/℃ |

| High strength thin tough cutter

Complex tools Simple tool Cold work mold |

850

850 850 850 |

1200~1220

1230 1240 1150~1200 |

Oil-cooled

Oil-cooled Oil-cooled Oil-cooled |

6. W6Mo5Cr4V2 application field

It is mainly used to manufacture various cutting tools with high cutting speed, heavy load and high working temperature, such as turning tools, milling tools, hobs, planers, broaches, drills, taps, etc., and can also be used to manufacture hot and cold deformation molds, high temperature springs, high temperature bearings, etc. that require high wear resistance.