Description

Scope of supply for Aviation Group

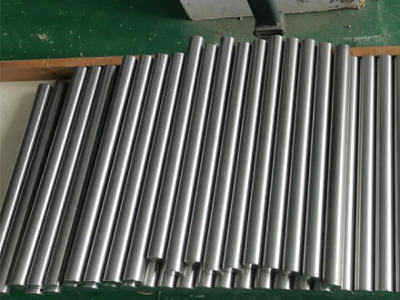

Forgings, round rods, steel plates, rings, seamless pipes, steel plates/steel belts, capillaries, wire welding materials, welcome to inquire

1. Material introduction

Hastelloy B3 (N10675) is a nickel-based high-temperature alloy composed of nickel, molybdenum, cobalt and other elements, with a nickel content of about 65%. Hastelloy B3 (N10675) nickel-based alloy material is a new material improved on the basis of Hastelloy B2, which improves the thermal stability of the material, thereby improving corrosion resistance, and improving the thermal forming and cold forming properties. In recent years, it has been increasingly used in the production and manufacturing of chemical equipment.

2. Chemical components

| alloy | % | In | Mo | Cr | Fe | W | Co | C | Mn | And | V | P | S | Cu | AL | Of | Nb | Facing | Zr | Ni+mo |

| B-3 | Minimum value | ≥65.0 | 27 | 1 | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 94 |

| Maximum value | 32 | 3 | 3 | 3 | 3 | 0.01 | 3 | 0.1 | 0.2 | 0.03 | 0.1 | 0.2 | 0.5 | 0.2 | 0.2 | 0.02 | 0.1 | 98 |

3. Physical properties

| density | 9.24g/cm3 |

| Melting point | 1370-1418 ℃ |

Minimum value of mechanical properties of alloys at room temperature:

| state | Tensile strength Rm N/mm | Yield strength RP0.2 N/mm | Elongation A5 % |

| Solid melting state | 760 | 350 | 40 |

4. Material characteristics

- B-3 alloy is a new member of the nickel-molybdenum alloy family, which has excellent corrosion resistance to any temperature and concentration of hydrochloric acid. At the same time, it also has good corrosion resistance to sulfuric acid, acetic acid, formic acid, phosphoric acid and other media that do not have oxidation properties.

- Due to adjustments to its chemical composition, its thermal stability has been greatly improved compared with the original B-2 alloy. B-3 alloy has high resistance to pitting corrosion, stress corrosion, cutting edge corrosion and heat-affected zone corrosion of welding.

- Metallographic structure of Hastelloy B-3: Hastelloy B-3 is a face-centered cubic lattice structure. The iron and chromium content of the alloy is controlled at a small value, thus hindering its precipitation of Ni4Mo phase between 700-800°C, thereby reducing the risk of processing embrittlement.

V. B-3 application fields

It has a wide range of applications in the fields of chemistry, petrochemical, energy manufacturing and pollution control, especially in industries such as sulfuric acid, hydrochloric acid, phosphoric acid, and acetic acid. However, like B-2 alloy, B-3 is not recommended for use in environments where trivalent iron salts and divalent copper salts exist, because these salts will quickly cause corrosion and damage. When hydrochloric acid comes into contact with iron and copper, it will react with it to form trivalent iron and divalent copper salts.