Description

Scope of supply of Aviation Group:

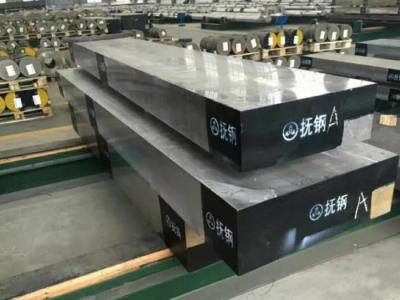

Non-standard forgings, round rods, steel plates, rings, seamless pipes

- Introduction to 0Cr15Ni7Mo2Al Materials

The precipitated hardened steel type with copper added with 0Cr15Ni7Mo2Al is developed by replacing 2% of chromium in 0Cr17Ni7Al steel with 2%-3% molybdenum. After heat treatment, the hardness is higher and the corrosion resistance is better. Its basic performance is similar to that of 0Cr17Ni7Al steel, but its comprehensive performance is better than that of it. In the austenite state, it can withstand various cold forming and welding processes, and then heat treatment can obtain the highest strength

- 0Cr15Ni7Mo2Al chemical composition

| alloy | C | Mn | And | P | S | Cr | In | Al | Mo |

| 0Cr15Ni7Mo2Al | – | – | – | – | – | 14.0 | 6.50 | 0.75 | 2.0 |

| 0.09 | 1.0 | 1.0 | 0.040 | 0.030 | 16.0 | 7.75 | 1.50 | 3.0 |

- 0Cr15Ni7Mo2Al Physical Properties

| density | 7.85g/cm3 |

| Melting point | 1415-1450℃ |

| state | Tensile strength MPa | Yield Strength MPa | Elongation after breaking | Section shrinkage rate % | HB | HRC |

| Solid solution | – | – | – | – | ≤269 | ≤26 |

| 565℃ aging | ≥1210 | ≥1100 | ≥7 | ≥25 | ≥375 | ≥42 |

| 510℃ aging | ≥1320 | ≥1210 | ≥6 | ≥20 | ≥388 | ≥44 |

- 0Cr15Ni7Mo2Al heat treatment

There are three heat treatment systems: TH1050 state, RH950 state, and CH900 state in A state.

Status A

After 1050℃ solid solution treatment, water-cool or air-cool. The metallographic structure is characterized by austenite.

TH1050 Status

After 1050℃ solid solution treatment, keep it at 760℃±15℃ for 90 minutes, air-cooled, cooled to 15℃ or room temperature within 1 hour, keep it for 30 minutes, and then heated to 565℃±10℃, keep it air-cooled, also known as 565℃ aging. The metallographic structure is characterized by precipitation hardened martensite.

RH950 status

After 1050℃ solid solution treatment, it is kept at 955℃±15℃ for 10 minutes, air-cooled to room temperature, cooled to -73℃±6℃ within 24 hours, maintained for 8 hours, and then heated to 510℃±6℃, and maintained for 60 minutes air-cooled, also known as 510℃ aging. The metallographic structure is characterized by precipitation hardened martensite.

CH900 status

After 1050℃ solid solution treatment, the cold rolling was 60% deformation, heated to 490℃ for 60 minutes, and air-cooled to room temperature. Metallographic structure is characterized by precipitation hardened martensite

- 0Cr15Ni7Mo2Al performance

Process performance includes cold and hot processing properties, heat treatment properties and welding properties.

0Cr15Ni7Mo2Al cold and hot processing performance

0Cr15Ni7Mo2Al stainless steel has an austenitic structure in solid solution and can withstand cold processing, but they all have a high tendency to harden cold work. Therefore, cold rolling, cold stamping, etc. are mostly processed using a process method with fewer passes, large pressure and multiple intermediate solid solution treatments. Its hot processing is not difficult, and the suitable hot processing temperature is 950-1150℃.

0Cr15Ni7Mo2Al heat treatment performance

The heat treatment of 0Cr15Ni7Mo2Al stainless steel is relatively complicated and has very strict requirements. Only by controlling the specified temperature, time and cooling speed can ideal performance be achieved.

0Cr15Ni7Mo2Al welding performance

The welding of 0Cr15Ni7Mo2Al stainless steel is the same as that of ordinary stainless steel. Arc welding, resistance welding and gas protection welding can be used, among which gas protection welding is the best. Welding is generally carried out in the solid solution state of the material. There is no need to preheat before welding, and it is best to perform the full heat treatment after welding. When the weld requires high strength, most of them are used to use 0Cr17Ni7A1 steel wire with low δ-ferritic content; when the weld strength requirements are not high and the corrosion resistance requirements are high, austenitic stainless steel wire can be used.

- 0Cr15Ni7Mo2Al application field

Welding and brazing honeycomb plates, aircraft partitions, and buckles are used to manufacture thin-walled structural parts of aviation, various containers, pipelines, springs, valve membranes, ship axles, compressor plates, reactor components, as well as a variety of chemical equipment and other structural parts.