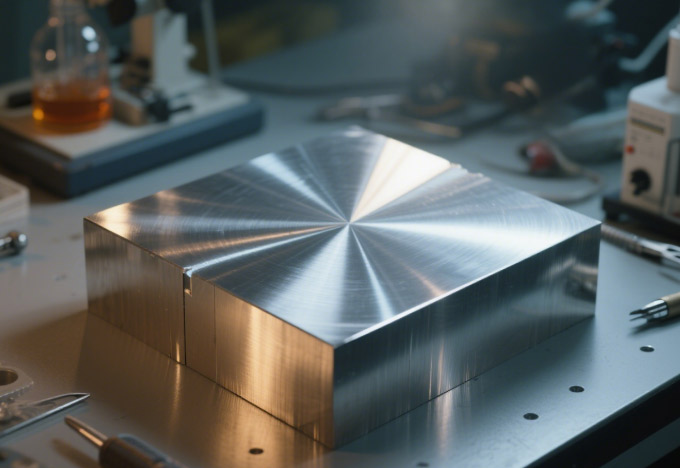

High-strength high-temperature alloys represent a critical class of materials that have garnered significant attention due to their unique combination of mechanical strength and resistance to extreme temperatures. These alloys are designed to maintain their structural integrity and performance under conditions that would cause conventional materials to fail, making them indispensable in various high-demand industries. Understanding the properties and applications of these alloys is essential for engineers and material scientists aiming to push the boundaries of what is possible in modern technology.

The defining characteristic of high-strength high-temperature alloys is their ability to sustain high levels of stress and temperature without degrading. This is achieved through a carefully balanced composition that typically includes elements such as nickel, chromium, iron, and cobalt. These elements contribute to the alloy’s strength by forming a robust crystal structure that can withstand thermal stress and mechanical loads. Additionally, the presence of alloys like molybdenum and tungsten enhances the material’s ability to retain its strength at elevated temperatures.

One of the most notable properties of these alloys is their excellent creep resistance. Creep is a time-dependent deformation that occurs under constant stress at high temperatures, and it can lead to material failure if not properly managed. High-strength high-temperature alloys mitigate this issue by incorporating elements that stabilize the crystal lattice, thereby reducing the tendency for atoms to move over time. This property is particularly crucial in applications where the materials are subjected to prolonged exposure to high temperatures, such as in gas turbines and jet engines.

Another important aspect of these alloys is their oxidation resistance. At high temperatures which can weaken the material and lead to failure. High-strength high-temperature alloys often include chromium, which forms a protective oxide layer on the surface of the material. This layer acts as a barrier, preventing further oxidation and preserving the integrity of the alloy. This property is essential in environments where the materials are exposed to hot gases or other corrosive elements.

The applications of high-strength high-temperature alloys are diverse and span multiple industries. In the aerospace sector, these alloys are used in the construction of aircraft engines, where they are subjected to extreme temperatures and pressures. The ability of these alloys to maintain their strength and resist degradation ensures that aircraft can operate safely and efficiently at high altitudes and speeds.

In the power generation industry, high-strength high-temperature alloys are used in the components of gas turbines and nuclear reactors. These applications require materials that can withstand continuous exposure to high temperatures and pressures, making the alloys ideal for such demanding environments. The longevity and reliability of these materials contribute to the overall efficiency and safety of power generation systems.

The automotive industry also benefits from the use of high-strength high-temperature alloys, particularly in the development of more efficient and powerful internal combustion engines. These alloys are used in critical components such as cylinder heads and exhaust manifolds, where they help to improve engine performance and durability.

In addition to these industrial applications, high-strength high-temperature alloys have found use in scientific research and experimental technologies. For instance, they are used in the construction of high-temperature superconducting magnets, which are essential for various scientific experiments and medical imaging devices. The ability of these alloys to maintain their structural integrity at extremely low temperatures makes them suitable for such specialized applications.

In conclusion, high-strength high-temperature alloys are a vital material in modern technology, offering a unique combination of strength and thermal resistance. Their properties, such as creep resistance and oxidation resistance, make them indispensable in industries that require materials capable of performing under extreme conditions. As technology continues to advance, the demand for these alloys is likely to grow, driving further innovation and development in their design and application. The ongoing research and exploration into these materials will continue to expand their potential uses, contributing to advancements in various fields and improving the efficiency and safety of numerous technologies.