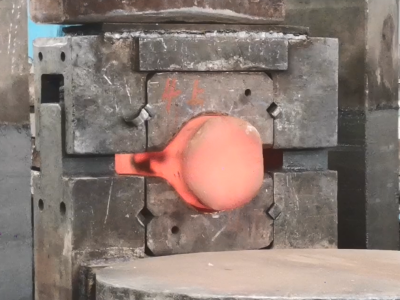

Description

Titanium forgings are customized according to the drawings

Titanium rod Φ(8-400) ×L≤5000mm (rolled rod, forged rod)

Titanium plate/belt (0.3-60.0) × (400-1000) × (1000-3500) mm (cold rolled plate, hot rolled plate)

Titanium tube Φ(3-210) × (0.2-10.0) ×L (rolled pipe, extruded pipe)

Titanium ring Outer diameter φ(100-1200) × Inner diameter Φ(100-1000) × Height (20-800) mm

Titanium round cake Φ(150-1200) × (20-800) mm

Titanium wire Φ(0.1-7.0) ×L

1. Introduction to TC4 Materials

Titanium alloy TC4 is a typical (α+β) type titanium alloy. The corresponding grade of TC4 is Ti-6Al-4V. Since it contains 6% of the α-stabilizing element Al and 4% of the β-stabilizing element V, TC4 has good comprehensive performance. It also has the advantages of low density, high specific strength, good corrosion resistance and good process performance. It is an ideal aerospace engineering structural material with a high specific strength.

Titanium alloy TC4 can be used in 400℃ for a long time. It is mainly used in the aviation industry to manufacture fans and compressor discs for engines, as well as important structural parts such as beams, joints and partitions in aircraft structures. TC4 is mainly used in annealed state, and can also be further used to make solution failure treatment. It has good process plasticity and superplasticity, and is suitable for various pressure processing and molding. Welding and machining can also be carried out in various ways.

2. TC4 chemical composition

| Brand number | Chemical composition (weight percentage) | |||||||||||

| Chemicai composition(WT%) | ||||||||||||

| TC4 | Chemical Ingredients | titanium | iron | carbon | nitrogen | hydrogen | oxygen | aluminum | vanadium | Other impurities | ||

| (Of) | (Fe) | (C) | (N) | (H) | (O) | (Al) | (V) | single | sum | |||

| Industrial pure titanium | margin | ≤0.30 | ≤0.10 | ≤0.05 | ≤0.015 | ≤0.25 | 5.5~6.8 | 3.5~4.5 | ≤0.10 | ≤0.40 | ||

3. TC4 Physical properties

TC4 titanium alloy density: 4.5 (g/cm3) Operating temperature -100~550 (℃)

TC4 strength sb=1.012GPa, specific strength sb/g=23.5, while the specific strength sb/g of alloy steel is less than 18.

| Brand number | Room temperature mechanical properties are not less than | High temperature mechanical properties are no less than | ||||||

| Tensile strength σb MPa | Yield strength σ0.2MPa | Elongation δ5% | Shrinkage ψ % | Impact value αk J/cm 2 | Test temperature ℃ | Tensile strength σb MPa | Long-lasting strength σ100 MPa | |

| TC1 | 588 | — | 15 | 30 | 44.1 | 350 | 343 | 324 |

| TC2 | 686 | — | 12 | 30 | 39.2 | 350 | 422 | 392 |

| TC4 | 902 | 824 | 10 | 30 | 39.2 | 400 | 618 | 569 |

| TC6 | 981 | — | 10 | 23 | 29.4 | 400 | 736 | 667 |

| TC9 | 1059 | — | 9 | 25 | 29.4 | 500 | 785 | 588 |

| TC10 | 1030 | — | 12 | 25~30 | 34.3 | 400 | 834 | 785 |

| TC11 | 1030 | — | 10 | 30 | 29.4 | 500 | 686 | 588 |

4. Technical standards for TC4 materials

GB/T3620.1-2016 Titanium and Titanium alloy grades and chemical compositions

GB/T 3621-2007 ASTM/B265 Titanium and Titanium alloy sheet

GB/T2965 -2007 ASTM/B348 Titanium and Titanium alloy rod

GB/T 3624-2010 ASTM337 Titanium and Titanium alloy seamless pipe

GB/T16598-2013 ASTM381 Titanium and Titanium alloy tubes for heat exchangers and condensers

GB/T13810-1997 AMST/F136 Titanium and Titanium alloy processing materials for surgical implants

GB/T3623-2007 AMST/B863 Titanium and Titanium alloy wire

AMST/B265 ASTM/B265 titanium and titanium alloy tapes and foils

TC4 heat treatment performance

TC4 titanium alloy heats to 1020 degrees, and the high-temperature microstructure of the alloy is composed of single-phase β, which is a solid solution. When the microstructures obtained are different at different cooling rates, such as water quenching, air cooling and furnace cooling, the microstructure obtained is different. The water quenching (WQ) structure is martensite α’+β phase, the air cooling (AC) structure is needle-shaped α+β phase and original β grain boundary phase, and the furnace cooling (FC) structure is strip-shaped α+β phase and original β phase grain boundary.

As in the above case, when heated to 950 degrees and 850 degrees, the microstructure obtained after cooling is also different after different cooling speeds. At 950 degrees, the quenched (WQ) tissue in water is the primary equiaxed α phase and α’+β phase, the air-cooled (AC) tissue is the primary equiaxed α phase and the needle-shaped β phase, and the furnace-cooled (FC) tissue is the primary equiaxed α phase and the grain boundary. At 850 degrees, the quenched (WQ) tissue in water is the primary equiaxed α phase and the metastable β phase, and the air-cooled (AC) tissue is the primary equiaxed α phase and the transformed β phase.

After heating to 1020 degrees, 950 degrees and 850 degrees, it cools at different cooling speeds. The room temperature mechanical properties are shown in Table 1

| Heating temperature and cooling method | Tensile strength/Mpa | Elongation/% | Surface shrinkage rate/% |

| 1020 degrees Swimming (WQ) | 1098 | 6.0 | 8.0 |

| 1020 degree air cooling (AC) | 1005 | 9.0 | 13.5 |

| 1020 degrees furnace cooling (FC) | 960 | 12.0 | 22.5 |

| 950 degrees Swimming (WQ) | 1035 | 17.0 | 61.5 |

| 950 degree air cooling (AC) | 919 | 20.0 | 50.0 |

| 950 degree furnace cooling (FC) | 902 | 21.0 | 48.0 |

| 850 degrees Swimming (WQ) | 976 | 18.0 | 49.0 |

| 850 degree air cooling (AC) | 951 | 18.0 | 49.0 |

5. TC4 application fields

- It is mainly used in aircraft compressor discs and blades, ship pressure-resistant shells, large-size forgings, die forgings, etc.;

- Used to manufacture rockets, missiles and aircraft structural parts, aircraft skeletons, skins, engine components, beams, etc.;

- Pipeline systems, valves, and pumps that are corroded by marine seawater;

- Power station condensers, accelerators for petroleum refining and seawater desalination, and environmental pollution control devices, etc.;

- Chemical heat exchanger, pump body, distillation tower;

- Widely used in medical devices