Description

Scope of supply for Aviation Group

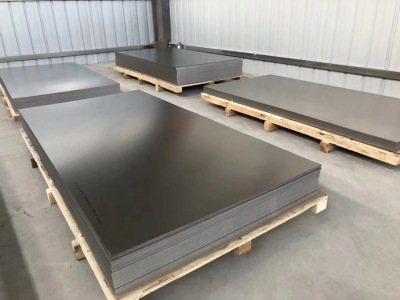

Forgings, round rods, steel plates, rings, seamless pipes, steel plates/steel belts, capillaries, wire welding materials, welcome to inquire!

Titanium forgings. Custom

titanium rods according to the drawings. Φ(8-400) ×L≤5000mm (rolled rods, forged rods)

titanium plate/belt (0.3-60.0) × (400-1000) × (1000-3500) mm (cold rolled plate, hot rolled plate)

titanium tube Φ(3-210) × (0.2-10.0) ×L (rolled pipes, extruded pipes)

titanium ring Outer diameter φ(100-1200) × inner diameter Φ(100-1000) × height (20-800) mm

titanium round cake Φ(150-1200) × (20-800) mm

titanium wire Φ(0.1-7.0) ×L

1. Introduction to TA18 materials

TA18 titanium alloy is a low alloying near-alpha titanium alloy. It has a nominal component of Ti-3Al-2.5V. It is developed as a cold-processable pipe application. It has good cold forming and welding properties. It has room temperature strength 20% to 50% higher than that of industrial pure titanium and has good corrosion resistance in many media. TA18 welding performance and cold forming performance are better than TC4 alloy.

TA18 titanium alloy seamless pipe is suitable for aircraft and engine hydraulic and fuel pipeline systems, and has been used in various military and civilian aircraft and aerospace applications. Therefore, TA18 titanium alloy has become the most suitable material for making high-pressure lightweight conduits on aircraft with its excellent comprehensive performance, and has become the most suitable material for making high-pressure lightweight conduits on aircraft.

2. Technical standards of TA18 materials

GB/T3620.1-2016 Titanium and Titanium Alloy Grades and Chemical Compositions

GB/T 3621-2007 ASTM/B265 Titanium and Titanium Alloy Sheet

GB/T2965 -2007 ASTM/B348 Titanium and Titanium Alloy Rod Material

GB/T 3624-2010 ASTM337 Titanium and Titanium Alloy Seamless Tube

GB/T16598-2013 Titanium and titanium alloy tubes for ASTM381 heat exchanger and condenser

GB/T13810-1997 Titanium and titanium alloy processing materials for AMST/F136 surgical implants

GB/T3623-2007 AMST/B863 titanium and titanium alloy wire

AMST/B265 ASTM/B265 Titanium and Titanium Alloy Band·Foil

3. Chemical composition of TA18

| Brand number | Chemical composition (weight percentage) | |||||||||||

| Chemicai composition(WT%) | ||||||||||||

| Ta18 | Chemical Ingredients | titanium | iron | carbon | nitrogen | hydrogen | oxygen | aluminum | vanadium | Other impurities | ||

| (Of) | (Fe) | (C) | (N) | (H) | (O) | (Al) | (V) | single | sum | |||

| Industrial pure titanium | margin | ≤0.25 | ≤0.08 | ≤0.05 | ≤0.015 | ≤0.12 | 2.0~3.5 | 1.5~3.0 | ≤0.10 | ≤0.40 | ||

4. TA18 physical properties

Density: 4.47g/cm³,

Room temperature elastic modulus 118~123GPa,

Phase change point: 925℃,

Hardness 15~17HRC.

Performance of TA18 titanium alloy specified by technical standards

| Technical standards | variety | state | Specifications/mm | Sampling direction | Room temperature performance | High temperature performance | |||||||

| Rm/MPa | Rp0.2/MPa | A/% | α / (º) | 350℃ | 400℃ | ||||||||

| Rm/MPa | σ100h/MPa | Rm/MPa | σ100h/MPa | ||||||||||

| Not less than | |||||||||||||

| GB/T3621-2007 | Plate | M | 0.5~1.0

>1.0~2.0 >2.0~4.0 >4.0~5.0 >5.0~10.0 |

LT | 590~735 | – | 25

25 20 15 15 |

100

70 60 60 |

340 | 320 | 310 | 280 | |

| GJB 3423a-2008 | Pipe | M | Outer diameter: >8~52 | LT | 620 | 515 | 15 | – | – | – | – | – | |

| GB/T26058-2010 | Pipe | R | 25~210 | LT | Actual test | Actual test | Actual test | – | – | – | – | – | |

5. TA18 application fields

- TA18 titanium alloy seamless pipe is suitable for aircraft and engine hydraulic and fuel pipeline systems, and has been used in various military and civilian aircraft and aerospace applications.

- TA18 titanium alloy has become the ideal material for making high-pressure lightweight conduits on aircraft with its excellent comprehensive performance. Become the ideal material for making high-pressure lightweight conduits on aircraft.