Description

Scope of supply for Aviation Group

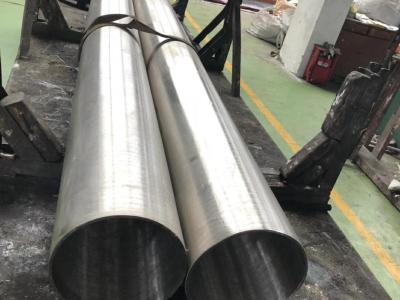

Forgings, round rods, steel plates, rings, seamless pipes, steel plates/steel belts, capillaries, wire welding materials, welcome to inquire!

1. Introduction to Incoloy800H/Incoloy800HT Materials

Incoloy 800H/800HT and 800 and alloy have the same chemical composition except for the different carbon content and the 800AT alloy, and the 800AT alloy also contains up to 1% aluminum and titanium. 800 alloy is generally used in temperature environments of about 593°C. 800H and 800AT alloys are usually used where higher creep and stress cracking resistance is required in temperature environments of about 593°C.

Incoloy 800HT can withstand corrosion of many corrosive media. Its high nickel content makes it have good stress corrosion cracking resistance in water-based corrosion conditions. The high chromium content makes it better resistance to pitting corrosion and crevice corrosion cracking. This alloy has good corrosion resistance of nitric acid and organic acids, but its corrosion resistance in sulfuric acid and hydrochloric acid is limited. In addition to the possibility of pit corrosion in halides, there is good corrosion resistance among oxidizing and non-oxidizing salts. It also has good corrosion resistance in water, steam, and mixtures of steam, air and carbon dioxide.

2. Chemical composition of Incoloy800H/Incoloy800HT

| alloy | % | In | Cr | Fe | C | Mn | And | Cu | P | S | Al | Of | Al+you |

| 800 | Minimum | 30 | 19 | margin | – | – | – | – | – | – | 0.15 | 0.15 | / |

| maximum | 35 | 23 | 0.10 | 1.5 | 1.0 | 0.75 | 0.030 | 0.015 | 0.60 | 0.60 | / | ||

| 800H | Minimum | 30 | 19 | margin | 0.05 | – | – | – | – | – | 0.15 | 0.15 | / |

| maximum | 35 | 23 | 0.10 | 1.5 | 1.0 | 0.75 | 0.045 | 0.015 | 0.60 | 0.60 | / | ||

| 800HT | Minimum | 30 | 19 | margin | 0.06 | – | – | – | – | / | / | 0.85 | |

| maximum | 35 | 23 | 0.10 | 1.5 | 1.0 | 0.75 | 0.02 | 0.010 | / | / | 1.20 |

3. Incoloy 800H/Incoloy 800HT physical performance

| density | 8.0 G / CM3 |

| Melting point | 1350-1400 ℃ |

Minimum value of mechanical properties of Incoloy 800H alloy at room temperature :

| alloy | tensile strength

Rm N/mm2 |

Yield of yield

RP0.2N/MM2 |

Elongation

A5 % |

| 800 | 500 | 210 | 35 |

| 800H | 450 | 180 | 35 |

4. Incoloy 800H/800HT has the following characteristics

- Excellent corrosion resistance in extremely high temperature aqueous media up to 500°C

- Very good stress corrosion resistance

- Very good processability

Metallographic structure of Incoloy 800H/800HT :

800H is a face-centered cubic lattice structure. The extremely low carbon content and the improved Ti:C ratio increase the stability of the structure and maximum antisensitization and resistance to intergranular corrosion. Low temperature annealing at around 950℃ ensures the fine crystal structure.

5. Corrosion resistance of Incoloy 800H/800HT:

800H can withstand corrosion of many corrosive media. Its high nickel content makes it have good stress corrosion cracking resistance in water-based corrosion conditions. The high chromium content makes it better resistance to pitting corrosion and crevice corrosion cracking. This alloy has good corrosion resistance of nitric acid and organic acids, but its corrosion resistance in sulfuric acid and hydrochloric acid is limited. In addition to the possibility of pit corrosion in halides, there is good corrosion resistance among oxidizing and non-oxidizing salts. It also has good corrosion resistance in water, steam, and mixtures of steam, air and carbon dioxide.

6. Incoloy 800H/800HT application field

- Nitric acid condenser–resistant to nitric acid corrosion

- Steam heating pipes – good mechanical properties

- Heating element tubes – good mechanical properties

For environments up to 500°C, the alloy supply state is annealed state.