Nickel-based superalloys are a critical class of materials that exhibit exceptional mechanical strength, creep resistance, and corrosion resistance at elevated temperatures. These alloys are primarily composed of nickel as the base element, supplemented with various alloying elements such as chromium, cobalt, tantalum, niobium, titanium, aluminum, and rhenium. The production process of nickel-based superalloys is complex and requires precise control of multiple parameters to achieve the desired microstructure and properties. The manufacturing process begins with the preparation of raw materials. High-purity nickel is typically used as the base metal, along with precisely weighed amounts of alloying elements. These materials are carefully selected and analyzed to ensure they meet the required chemical specifications. Impurities are minimized as they can significantly affect the final properties of the superalloy.  The next step is melting, which is typically performed in vacuum induction furnaces (VIF) or vacuum arc remelting (VAR) systems. Vacuum melting is essential to prevent contamination by oxygen, nitrogen, and other gases that could form detrimental phases or reduce the alloy’s performance. The melting process may involve multiple remelting cycles to ensure chemical homogeneity and removal of non-metallic inclusions. Temperature control during melting is critical, as overheating can lead to excessive evaporation of alloying elements, particularly those with high vapor pressures like manganese. After melting, the molten alloy is cast into ingots using various casting methods. Conventional casting techniques include investment casting and directional solidification. Investment casting is suitable for producing complex components with near-net shapes, while directional solidification techniques such as single crystal casting enhance the creep resistance of the superalloy by eliminating grain boundaries in the loading direction. The cooling rate during solidification significantly influences the microstructure, particularly the size and distribution of gamma prime (γ’) precipitates, which are crucial for the alloy’s high-temperature strength.

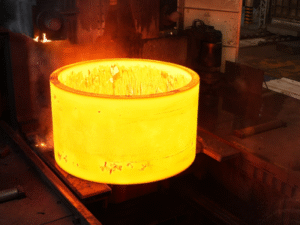

The next step is melting, which is typically performed in vacuum induction furnaces (VIF) or vacuum arc remelting (VAR) systems. Vacuum melting is essential to prevent contamination by oxygen, nitrogen, and other gases that could form detrimental phases or reduce the alloy’s performance. The melting process may involve multiple remelting cycles to ensure chemical homogeneity and removal of non-metallic inclusions. Temperature control during melting is critical, as overheating can lead to excessive evaporation of alloying elements, particularly those with high vapor pressures like manganese. After melting, the molten alloy is cast into ingots using various casting methods. Conventional casting techniques include investment casting and directional solidification. Investment casting is suitable for producing complex components with near-net shapes, while directional solidification techniques such as single crystal casting enhance the creep resistance of the superalloy by eliminating grain boundaries in the loading direction. The cooling rate during solidification significantly influences the microstructure, particularly the size and distribution of gamma prime (γ’) precipitates, which are crucial for the alloy’s high-temperature strength.  Following casting, the as-cast ingots undergo homogenization heat treatment to eliminate chemical segregation and achieve a uniform composition. This is typically performed at temperatures between 1100°C and 1250°C for several hours. The homogenized material is then hot worked through processes such as forging, rolling, or extrusion to break down the cast structure and refine the grain size. The hot working parameters, including temperature, strain rate, and total reduction, must be carefully controlled to prevent the formation of defects and ensure optimal microstructural characteristics. Heat treatment is a critical step in the production of nickel-based superalloys. Solution treatment is performed to dissolve undesirable phases and achieve a uniform solid solution. This is followed by aging treatment, which involves controlled cooling and holding at specific temperatures to precipitate the strengthening gamma prime phase. The precise control of temperature and time during aging is essential to achieve the optimal size, distribution, and volume fraction of gamma prime precipitates, which determine the alloy’s mechanical properties at high temperatures. Final processing may include additional heat treatments, machining, and surface treatments to meet specific application requirements. Non-destructive testing is performed throughout the production process to ensure the absence of defects and compliance with quality standards. The resulting nickel-based superalloys find applications in gas turbine engines, aerospace components, nuclear reactors, and other high-temperature environments where conventional materials would fail.

Following casting, the as-cast ingots undergo homogenization heat treatment to eliminate chemical segregation and achieve a uniform composition. This is typically performed at temperatures between 1100°C and 1250°C for several hours. The homogenized material is then hot worked through processes such as forging, rolling, or extrusion to break down the cast structure and refine the grain size. The hot working parameters, including temperature, strain rate, and total reduction, must be carefully controlled to prevent the formation of defects and ensure optimal microstructural characteristics. Heat treatment is a critical step in the production of nickel-based superalloys. Solution treatment is performed to dissolve undesirable phases and achieve a uniform solid solution. This is followed by aging treatment, which involves controlled cooling and holding at specific temperatures to precipitate the strengthening gamma prime phase. The precise control of temperature and time during aging is essential to achieve the optimal size, distribution, and volume fraction of gamma prime precipitates, which determine the alloy’s mechanical properties at high temperatures. Final processing may include additional heat treatments, machining, and surface treatments to meet specific application requirements. Non-destructive testing is performed throughout the production process to ensure the absence of defects and compliance with quality standards. The resulting nickel-based superalloys find applications in gas turbine engines, aerospace components, nuclear reactors, and other high-temperature environments where conventional materials would fail.

- +86-18921275456

- NO. 21 Zhihui Road, Huishan District, Wuxi, Jiangsu, China

Оставайтесь на связи - подпишитесь на нашу рассылку

О США

После многих лет развития мы установили долгосрочные и стабильные отношения сотрудничества со многими отечественными и зарубежными материа...

Контактная информация

- Мобильный: +86-18921275456

- Whatsapp:8618921275456

- Адрес: NO. 21 Zhihui Road, Huishan District, Wuxi, Jiangsu, China