Stainless Steel and High-Temperature Alloys: A Guide to Properties, Applications, and Selection

In modern industrial material selection, stainless steel and high-temperature alloys are often considered – both possess excellent corrosion resistance, but there are significant differences in core characteristics such as high temperature resistance and mechanical strength, with each having its own emphasis on applicable scenarios. The following analysis will be conducted from the aspects of material definition, performance comparison, application fields, and selection strategies, providing a clear reference for industrial selection

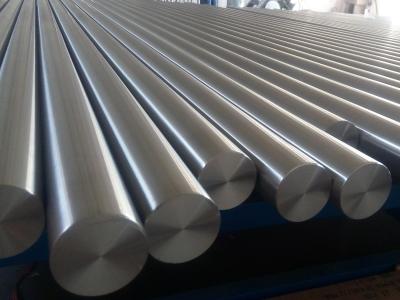

From the perspective of material definition, stainless steel and high-temperature alloys have fundamentally different positioning. Stainless steel is a steel material based on iron, containing a sufficient amount of chromium (the core corrosion-resistant component), and may be supplemented with alloying elements such as nickel, molybdenum, titanium, and niobium. Its core advantage lies in its strong corrosion resistance at room temperature. Chromium forms a dense oxide film on the surface, which can isolate it from the erosion of oxygen, water, and acid-base media, while also possessing good processability and economy. According to its microstructure, stainless steel can be divided into austenitic (such as 304, 316L), ferritic (such as 430), martensitic (such as 410), and other types. Among them, austenitic stainless steel, due to its strong corrosion resistance and good toughness, accounts for a very high proportion of global stainless steel production and is widely used in kitchenware, construction, medical equipment, and other fields. On the other hand, high-temperature alloys are high-end alloy materials based on iron, nickel, and cobalt (with nickel-based alloys accounting for the highest proportion), supplemented with elements such as Cr, Mo, W, Al, and Ti. They are specifically designed for high-temperature and stress environments, and their core advantage lies in their ability to maintain high strength (creep resistance, fatigue resistance), strong oxidation/thermal corrosion resistance, and excellent microstructural stability (no performance degradation after long-term service). Classified by matrix, high-temperature alloys mainly include nickel-based (such as GH4169, Inconel 625), iron-based (such as GH2132), and cobalt-based (such as GH5605) types. Among them, nickel-based high-temperature alloys, due to their high upper limit of temperature tolerance and excellent comprehensive performance, have become an “irreplaceable material” in high-end fields such as aero-engines and nuclear power.

In terms of core performance comparison, the differences between the two are quite evident. In terms of temperature resistance, stainless steel is suitable for lower temperature ranges, and its strength significantly decreases once it exceeds a certain temperature. On the other hand, high-temperature alloys can withstand temperatures much higher than stainless steel and exhibit more stable performance in high-temperature environments. In terms of corrosion resistance, stainless steel is resistant to room temperature acids and alkalis. For example, 304 stainless steel is resistant to neutral salt spray, and 316L stainless steel is resistant to mild corrosion. However, high-temperature alloys are resistant to high-temperature corrosion. For instance, Inconel 625 can withstand high-temperature sulfide erosion, indicating that high-temperature alloys can adapt to extreme corrosive environments (such as high-temperature sulfide and molten salt). Stainless steel is only suitable for room temperature corrosion scenarios. The mechanical properties of the two materials diverge even more under high-temperature conditions. Stainless steel exhibits a significant decrease in tensile strength in high-temperature environments and is prone to creep. On the other hand, high-temperature alloys such as GH4169 maintain high tensile strength even at high temperatures and exhibit outstanding creep resistance, with essentially no risk of plastic deformation. In terms of processability, stainless steel is easy to cut, weld, and bend. For example, 304 stainless steel can be cold-worked and formed. High-temperature alloys, on the other hand, are more difficult to process and require special processes such as vacuum melting and single crystal casting. Specialized techniques are also required for welding. The processing cost of stainless steel is much lower than that of high-temperature alloys. In terms of material cost, stainless steel is relatively inexpensive, while high-temperature alloys are significantly more expensive and rely on scarce elements such as cobalt and rhenium. In terms of structural stability, stainless steel tends to precipitate carbides at higher temperatures, which may lead to intergranular corrosion. High-temperature alloys, on the other hand, maintain a single austenite structure even after long-term service at high temperatures without phase transformation, meeting the requirements for long-term high-temperature service.

The differences in application fields are determined by the performance characteristics of the two materials. Stainless steel, with its advantages of “high cost-effectiveness, easy processing, and corrosion resistance”, is widely used in non-extreme environments. In the field of people’s livelihood, stainless steel is heavily utilized in kitchen utensils (304 stainless steel pots and sinks), tableware (corrosion-resistant and easy to clean), and household appliances (inner tub of washing machines, inner tank of water heaters). In the field of architectural decoration, stainless steel is often chosen for curtain wall panels (304 brushed stainless steel, beautiful and durable), door and window frames (430 ferritic stainless steel, low cost), and urban sculptures (resistant to atmospheric corrosion). In conventional industries, stainless steel is also indispensable for chemical equipment (316L storage tanks, pipelines, resistant to weak acids and alkalis), medical devices (316L surgical instruments, no nickel release risk), and automotive components (exhaust pipes, water tanks, resistant to normal temperature corrosion). High-temperature alloys, due to their “adaptability to extreme environments”, have become core materials for high-end equipment. In the aerospace industry, aviation engine hot-end components (turbine blades made of single crystal nickel-based alloy, resistant to extremely high temperatures), missile nozzles (cobalt-based alloy, resistant to high-temperature erosion), and spacecraft thermal protection panels (GH3044, resistant to high-temperature radiant heat) all utilize high-temperature alloys. In the energy sector, gas turbines (combustion chambers made of GH3536, resistant to high-temperature gas corrosion), nuclear power evaporators (heat transfer tubes made of Inconel 690, resistant to high-temperature and high-pressure water corrosion), and ultra-supercritical units (boiler tubes made of GH2132, resistant to high-pressure steam) also rely on high-temperature alloys. In special industries, high-temperature alloys also play an irreplaceable role in scenarios such as petrochemical cracking furnaces (furnace tubes made of GH3044, resistant to high-temperature cracking gas corrosion), glass kilns (spray nozzles made of cobalt-based alloy, resistant to high-temperature glass melt erosion), and medical implant devices (cobalt-based alloy artificial joints, resistant to body fluid corrosion and high strength).

In terms of selection strategy, the core needs to revolve around three major dimensions: “usage environment, performance requirements, and cost budget”. Firstly, priority should be given to determining temperature requirements. If the operating temperature is in the lower range (such as normal temperature storage tanks, building decoration), stainless steel (304/316L) can be directly selected, balancing cost and corrosion resistance. If the operating temperature is in the medium range (such as medium temperature heating furnaces), high temperature resistant stainless steel (such as 310S) can be chosen, with a lower cost compared to high temperature alloys. If the operating temperature is in the high range (such as aero-engines, nuclear power), high temperature alloys (nickel-based/cobalt-based) must be selected to avoid material failure at high temperatures. Secondly, it is necessary to consider the intensity of the corrosive environment. In scenarios with weak corrosion at normal temperature (such as atmospheric air, fresh water), stainless steel 304 can meet the requirements. In scenarios with strong corrosion at normal temperature (such as seawater, acidic solutions), corrosion-resistant stainless steel (316L, 254SMO) should be selected. In high temperature corrosion environments (such as high temperature sulfides, molten salts), only high temperature alloys (such as Inconel 625, Hastelloy C-276) can withstand the corrosion. Finally, cost and processing feasibility must also be considered. For mass civilian and conventional industrial scenarios, stainless steel is the only economical choice due to its convenient processing and low cost. For key components of high-end equipment, even if high temperature alloys are costly, they must be selected to avoid equipment failure caused by material failure, which would increase maintenance costs. For composite scenarios, a “high-low combination” solution can be adopted. For example, in aero-engines, high temperature alloys are used for turbine blades to ensure performance, while stainless steel is used for the casing to control cost and weight.

In general, stainless steel and high-temperature alloys are not in a “replacement relationship” but rather a “complementary scenario” – the former is a “general-purpose corrosion-resistant material” supporting people’s livelihood and conventional industries; the latter is a “high-end extreme environment material” ensuring the reliability of high-end equipment. When selecting materials, it is necessary to break away from the misconception that “higher performance is better” and instead focus on “scenario requirements”: use stainless steel for normal temperature environments and choose alloys for high temperature environments; use stainless steel for conventional corrosion scenarios and choose alloys for extreme corrosion scenarios; use stainless steel for cost-sensitive scenarios and choose alloys for performance-priority scenarios. Only by accurately matching requirements can the optimal balance between “performance compliance” and “cost controllability” be found, laying the foundation for long-term stable operation of equipment.