The high-temperature alloy die-casting process represents a critical manufacturing method for producing components that must withstand extreme conditions. This specialized process involves the melting and injection of heat-resistant alloys into molds to create complex, durable parts used in demanding applications.

High-temperature alloys, typically composed of nickel, cobalt, iron, and various refractory elements, possess exceptional mechanical properties at elevated temperatures. These alloys maintain strength, creep resistance, and oxidation resistance under conditions that would cause conventional materials to fail. The die-casting of these alloys requires precise temperature control, specialized equipment, and carefully designed molds to ensure proper filling and solidification.

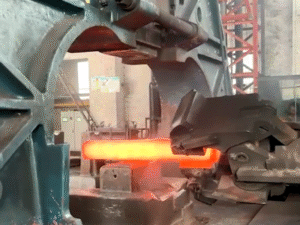

The process begins with the preparation of the alloy, which is typically melted in induction furnaces to temperatures ranging from 1350°C to 1500°C, depending on the specific alloy composition. The molten metal is then transferred to a ladle and injected into the die cavity under high pressure, usually between 10 to 175 MPa. The injection speed and pressure must be carefully controlled to ensure complete mold filling without causing turbulence or gas entrapment.

Die temperature control is crucial in high-temperature alloy die-casting. Preheating the die to 200-300°C helps thermal shock and improves metal flow. Cooling channels within the die must be strategically positioned to control solidification rates, which directly affects the microstructure and mechanical properties of the final component.

After solidification, the casting is ejected from the mold and may undergo various post-processing treatments. Heat treatment is often necessary to optimize the mechanical properties, while machining may be required to achieve precise dimensional tolerances. Non-destructive testing methods, including X-ray inspection and ultrasonic testing, are employed to detect internal defects and ensure quality.

The applications of high-temperature alloy die-castings span numerous industries, including aerospace, automotive, energy generation, and industrial manufacturing. Turbine components, exhaust systems, and heat exchangers represent common applications where these materials provide superior performance and reliability.

Advancements in simulation technology have significantly improved the high-temperature alloy die-casting process. Computer-aided engineering tools allow engineers to predict fluid flow, heat transfer, and solidification behavior before physical trials, reducing development time and costs while improving quality.

Despite its advantages, the die-casting of high-temperature alloys presents challenges, including mold life limitations, high energy consumption, and the formation of surface defects. Ongoing research focuses on developing new alloys with improved castability, enhancing mold materials for longer service life, and optimizing process parameters for greater efficiency and quality.

As industries continue to demand higher performance components operating under increasingly severe conditions, the high-temperature alloy die-casting process will continue to evolve, offering innovative solutions for the most demanding engineering challenges.