Performance Testing of Titanium Alloys: A Comprehensive Analysis

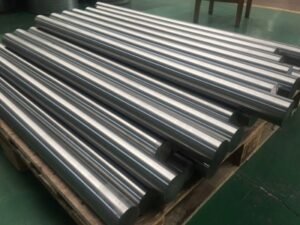

Performance testing of titanium alloys is a critical process in the aerospace, medical, and automotive industries, where material strength, durability, and resistance to extreme conditions are paramount. This article provides a detailed examination of the methodologies and significance of performance testing for titanium alloys, focusing on the factors that influence their suitability for various applications. The analysis begins with an overview of titanium alloys, highlighting their unique properties such as high strength-to-weight ratio, corrosion resistance, and biocompatibility. These characteristics make titanium alloys ideal for use in environments where traditional materials would fail.

To begin with, the performance testing of titanium alloys involves a series of standardized procedures designed to evaluate their mechanical and physical properties. These tests include tensile testing, which measures the alloy’s ability to withstand stretching forces, and hardness testing, which assesses its resistance to indentation. Additionally, fatigue testing is conducted to determine how the material performs under cyclic loading, which is crucial for components that experience repeated stress, such as aircraft wings and engine parts. Each test provides valuable data that helps engineers understand the limitations and capabilities of titanium alloys in real-world conditions.

Environmental testing is another essential aspect of performance evaluation. Titanium alloys are often exposed to extreme temperatures, corrosive substances, and high pressures, making it imperative to assess their stability under these conditions. Heat resistance testing, for instance, evaluates how the material retains its structural integrity when subjected to elevated temperatures, while corrosion resistance testing determines its ability to withstand chemical attacks. These tests are particularly important in the aerospace industry, where titanium components must operate in harsh environments without degrading.

The significance of performance testing cannot be overstated, as it directly impacts the design and reliability of products that use titanium alloys. By thoroughly analyzing the material’s properties, engineers can optimize the design of components, ensuring they meet the stringent requirements of their intended applications. For example, in the medical field, performance testing helps in creating implants that are both biocompatible and durable, reducing the risk of failure and improving patient outcomes. Similarly, in the automotive industry, the results of these tests guide the development of lightweight and high-strength parts that enhance vehicle performance and fuel efficiency.

In conclusion, performance testing of titanium alloys is a comprehensive and meticulous process that involves evaluating a range of mechanical, physical, and environmental factors. The insights gained from these tests are invaluable for engineers and designers, enabling them to harness the full potential of titanium alloys in various industries. As technology advances, the demand for high-performance materials like titanium alloys continues to grow, making performance testing an increasingly critical component of material development and application.