Optimizing GH4169 Nickel-Based High-Temperature Alloy Sheet for Enhanced Performance and Durability

In the realm of high-performance materials, the GH4169 nickel-based high-temperature alloy sheet stands out as a prime candidate for various critical applications. This article delves into the intricacies of optimizing the GH4169 alloy sheet to enhance its performance and durability, thereby broadening its applicability across diverse industries.

The GH4169 alloy, renowned for its exceptional heat resistance and strength, is a blend of nickel, chromium, molybdenum, and cobalt. These elements are meticulously combined to create a material that can withstand extreme temperatures and harsh environments. However, the performance of the GH4169 alloy sheet can be further improved through optimization techniques.

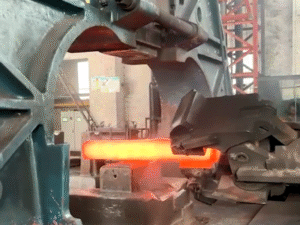

One of the primary methods to optimize the GH4169 alloy sheet is through heat treatment. Heat treatment involves heating the material to a specific temperature and then cooling it at a controlled rate. This process can alter the microstructure of the alloy, thereby enhancing its mechanical properties. By carefully controlling the heating and cooling rates, it is possible to achieve a fine-grained structure, which improves the alloy’s strength and toughness.

Another critical aspect of optimizing the GH4169 alloy sheet is surface treatment. Surface treatment techniques, such as shot peening, can improve the material’s fatigue resistance and reduce the likelihood of cracking. Shot peening involves bombarding the surface of the alloy sheet with small metal beads at high velocity. This process creates compressive residual stresses on the surface, which helps to prevent crack propagation.

Additionally, the addition of alloying elements can further enhance the performance of the GH4169 alloy sheet. For instance, the inclusion of titanium and aluminum can improve the alloy’s oxidation resistance and creep strength. These elements form a protective oxide layer on the surface of the material, which helps to prevent degradation at high temperatures.

In the realm of material processing, the choice of rolling technique plays a vital role in optimizing the GH4169 alloy sheet. The rolling process can be tailored to achieve specific mechanical properties, such as tensile strength and hardness. By adjusting the rolling parameters, such as the temperature, strain rate, and reduction ratio, it is possible to fine-tune the microstructure and mechanical properties of the alloy sheet.

Moreover, the use of advanced simulation and analysis tools can aid in optimizing the GH4169 alloy sheet. These tools allow engineers to predict the behavior of the material under various conditions, thereby enabling them to make informed decisions during the design and manufacturing process. By simulating the effects of heat treatment, surface treatment, and processing techniques, engineers can identify the most effective optimization strategies.

In conclusion, the GH4169 nickel-based high-temperature alloy sheet is a versatile material with vast potential applications. By employing various optimization techniques, such as heat treatment, surface treatment, alloying, and advanced material processing, it is possible to enhance the performance and durability of this alloy sheet. As industries continue to seek materials that can withstand extreme conditions, the optimized GH4169 alloy sheet is poised to become an indispensable component in numerous applications, from aerospace to power generation.