説明

アビエーション・グループへの供給範囲

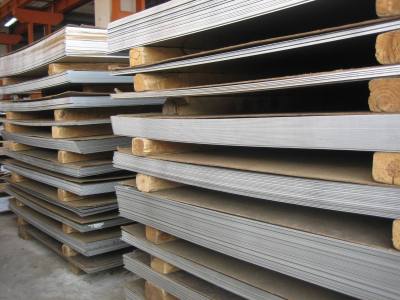

鍛造品、丸棒、鋼板、リング、シームレスパイプ、鋼板/スチールベルト、キャピラリー、ワイヤ溶接材料、お問い合わせ歓迎!

チタン鍛造品カスタム

図面に従ってチタン棒。Φ(8-400) ×L≤5000mm (圧延棒、鍛造棒)

チタン板/ベルト(0.3~60.0)×(400~1000)×(1000~3500)mm(冷延板、熱延板)

チタン管Φ(3-210)×(0.2-10.0)×L(圧延管、押出管)

チタンリング 外径φ(100~1200)×内径φ(100~1000)×高さ(20~800)mm

チタン丸餅Φ(150~1200)×(20~800)mm

チタン線 Φ(0.1-7.0) ×L

1. Introduction to TA3/Gr3 materials

TA3 is industrial pure titanium. They have high mechanical properties, excellent stamping properties, and can be welded in various forms. The strength of the welded joint can reach 90% of the metal strength of the matrix, and have good cutting performance. Titanium tubes have high corrosion resistance to chloride, sulfide and ammonia. Titanium has higher corrosion resistance in seawater than aluminum alloys, stainless steel, and nickel-based alloys. Titanium has strong water impact resistance.

2. Chemical composition of TA3/Gr3

| ブランド番号 | 化学組成(重量パーセント)

化学組成(WT%) |

||||||||

| TA3 | 化学成分 | チタン | アイアン | カーボン | 窒素 | 水素 | 酸素 | その他の不純物 | |

| の | 鉄 | (C) | (N) | (H) | (O) | シングル | 合計 | ||

| 工業用純チタン | マージン | ≤0.40 | ≤0.10 | ≤0.05 | ≤0.015 | ≤0.30 | ≤0.1 | ≤0.4 | |

3. Physical properties of TA3/Gr3

| ブランド番号 | 室温での機械的特性は以下の通り。 | 高温での機械的特性は | ||||||

| 引張強さ σb MPa | 降伏強度 σ0.2MPa | エロンゲーション δ5% | 収縮率 ψ % | 衝撃値 αk J/cm 2 | 試験温度 | 引張強さ σb MPa | 長持ち強度 σ100 MPa | |

| Ta1 | 343 | 275 | 25 | 50 | — | |||

| TA2 | 441 | 373 | 20 | 40 | — | |||

| TA3 | 539 | 461 | 15 | 35 | — | |||

| Ta5 | 686 | — | 15 | 40 | 58.8 | |||

| Ta6 | 686 | — | 10 | 27 | 29.4 | 350 | 422 | 392 |

| TA7 | 785 | — | 10 | 27 | 29.4 | 350 | 490 | 441 |

| TC1 | 588 | — | 15 | 30 | 44.1 | 350 | 343 | 324 |

| TC2 | 686 | — | 12 | 30 | 39.2 | 350 | 422 | 392 |

| TC4 | 902 | 824 | 10 | 30 | 39.2 | 400 | 618 | 569 |

| TC6 | 981 | — | 10 | 23 | 29.4 | 400 | 736 | 667 |

| TC9 | 1059 | — | 9 | 25 | 29.4 | 500 | 785 | 588 |

| TC10 | 1030 | — | 12 | 25~30 | 34.3 | 400 | 834 | 785 |

| TC11 | 1030 | — | 10 | 30 | 29.4 | 500 | 686 | 588 |

4. Technical standards of TA3/Gr3 materials

GB/T3620.1-2016 チタンおよびチタン合金の等級と化学組成

GB/T 3621-2007 ASTM/B265 チタンおよびチタン合金シート

GB/T2965 -2007 ASTM/B348 チタニウムおよびチタニウムの合金棒材料

GB/T 3624-2010 ASTM337 チタンおよびチタン合金シームレス管

GB/T16598-2013 ASTM381熱交換器およびコンデンサーのためのチタニウムおよびチタニウム合金の管

GB/T13810-1997 AMST/F136 外科インプラント用チタンおよびチタン合金加工材料

GB/T3623-2007 AMST/B863 チタンおよびチタン合金ワイヤー

AMST/B265 ASTM/B265 チタンおよびチタン合金バンドフォイル

5. Six major characteristics of TA3/Gr3

1. High strength: Titanium has better strength/density ratio than other metals, and can be made of titanium to make components with high strength, good rigidity and light weight. Titanium is used in aircraft engines, frames, skins, fasteners and landing gear.

2. Anti-corrosion: Compared with stainless steel, titanium alloy has better corrosion effect in humid air and seawater, and titanium has great resistance to pit corrosion, acid corrosion and stress corrosion. Titanium resists corrosion of alkali, chloride, chlorinated organic matter, sulfuric acid, nitric acid.

3. High temperature resistance: The application temperature of titanium is higher than that of aluminum alloy. Titanium can work for a long time at 450-500℃.

4. Low temperature resistance: When working at low temperature or ultra-low temperature conditions, titanium alloys still have their mechanical properties. Titanium alloys with low temperature resistance and extremely low gaps still have good ductility, so titanium alloys are a good low temperature structural material.

5. Environmentally friendly metals: Titanium has lower thermal conductivity than carbon steel or copper, but titanium has very good corrosion resistance. Therefore, the thickness of titanium can be greatly reduced, and the heat exchange mode is dropwise condensation between titanium and steam. This mode reduces heat transfer resistance and there is no scaling on the titanium surface, thus making the titanium more thermal conductivity.

6. Good thermal conductivity: Titanium is a non-magnetic metal and cannot be magnetized in large magnetic fields. Moreover, titanium is non-toxic and compatible with blood, so titanium has been used in the medical field.

6. TA3/Gr3 応用分野

- Used to make airplane engine compressor parts;

- ロケット、ミサイル、航空機の構造部品、航空機の骨格、外皮、エンジン部品、梁などの製造に使用される;

- 海水によって腐食するパイプラインシステム、バルブ、ポンプ;

- Power station condensers, accelerators for petroleum refining and seawater desalination, and environmental pollution control devices, etc.

- Chemical heat exchanger, pump body, distillation tower.