High-temperature alloy flanges represent critical components in various industrial applications where extreme conditions prevail. These specialized flanges are engineered from advanced materials capable of maintaining structural integrity under intense heat, pressure, and corrosive environments. The customization process ensures that each flange meets specific operational requirements, making them indispensable in sectors such as aerospace, energy production, chemical processing, and petrochemical industries.

The manufacturing of customized high-temperature alloy flanges begins with material selection. Nickel-based superalloys, cobalt-chromium alloys, and iron-nickel-chromium compositions are commonly chosen for their exceptional thermal stability and mechanical properties. These materials demonstrate superior resistance to oxidation, creep, and thermal fatigue, which are essential characteristics for components operating in temperatures exceeding 1000 degrees Fahrenheit. The alloy composition is carefully formulated to balance strength, durability, and workability, ensuring the final product can withstand prolonged exposure to harsh conditions.

The customization process involves several precision engineering steps. Initial design considerations include operating temperature parameters, pressure ratings, dimensional specifications, and environmental factors. Computer-aided design software enables engineers to create detailed models that optimize flange geometry for maximum performance. Finite element analysis helps predict stress distribution and potential failure points, allowing for design refinements before production begins. This analytical approach ensures that each customized flange meets or exceeds industry standards while addressing unique application requirements.

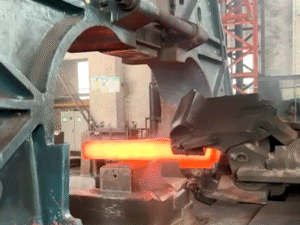

Manufacturing techniques for high-temperature alloy flanges include forging, machining, and heat treatment. Forging processes align the grain structure of the alloy, enhancing its mechanical properties and reducing the likelihood of defects. Precision machining ensures dimensional accuracy and proper surface finish, which are critical for leak-proof connections. Heat treatment procedures further optimize the material’s microstructure, improving its high-temperature performance characteristics. Quality control measures at each production stage guarantee consistent material properties and dimensional tolerances.

Applications for customized high-temperature alloy flanges span multiple industries. In power generation, these components facilitate connections in boiler systems, steam turbines, and heat recovery units. The aerospace sector utilizes specialized flanges in jet engines and spacecraft propulsion systems where reliability under extreme conditions is paramount. Chemical processing plants employ corrosion-resistant alloy flanges to handle aggressive substances at elevated temperatures. Oil and gas exploration relies on robust flange connections for drilling equipment and pipeline systems operating in subsea and high-temperature environments.

Selecting appropriate high-temperature alloy flanges requires careful evaluation of several factors. Operating temperature ranges determine the suitable alloy composition, while pressure ratings influence flange thickness and design standards. Environmental considerations such as exposure to corrosive elements or thermal cycling necessitate specific material selections. Installation procedures must follow established guidelines to ensure proper sealing and alignment. Maintenance protocols should include regular inspection for signs of degradation, particularly in critical applications.

The future of high-temperature alloy flange technology continues to evolve with advancements in materials science and manufacturing processes. Research efforts focus on developing alloys with enhanced properties, improved manufacturing techniques for greater precision, and more efficient design methodologies. As industrial processes become increasingly demanding, the role of customized high-temperature alloy flanges will continue to expand, driven by the need for reliable components capable of performing in extreme environments. The ongoing innovation in this field ensures that these critical components will meet the challenges of tomorrow’s industrial applications.