Nitriding Treatment of Titanium Alloys: Process, Benefits, and Applications

Titanium alloys are renowned for their exceptional strength, lightweight nature, and biocompatibility, making them indispensable in various industries such as aerospace, medical implants, and automotive components. To further enhance their properties, nitriding treatment is often employed. This process involves the introduction of nitrogen into the titanium alloy’s surface, resulting in the formation of a hard, wear-resistant nitride layer. The nitriding treatment of titanium alloys encompasses a detailed process, offers numerous benefits, and finds extensive applications across different sectors.

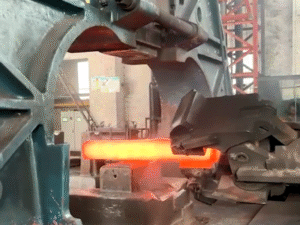

The nitriding process begins with the preparation of the titanium alloy surface, which is cleaned and degreased to ensure optimal adhesion of the nitride layer. The alloy is then placed in a nitriding chamber where a controlled atmosphere of nitrogen and other gases is introduced. The process can be carried out at temperatures ranging from 450 to 900 degrees Celsius, depending on the desired properties of the nitride layer. During this stage, nitrogen atoms diffuse into the surface of the titanium alloy, forming titanium nitride (TiN) and other nitrides. The duration of the nitriding treatment varies based on the thickness of the nitride layer required, typically ranging from a few hours to several days.

One of the primary benefits of nitriding treatment is the significant improvement in surface hardness and wear resistance. The formed nitride layer acts as a protective barrier, preventing the underlying titanium alloy from corrosion and wear. This enhanced durability makes nitrided titanium alloys particularly suitable for applications where the components are subjected to high stress and abrasive conditions. Additionally, the nitriding process increases the fatigue strength of the alloy, further extending its service life.

Another notable advantage is the biocompatibility of nitrided titanium alloys, which is crucial for medical applications. The nitride layer does not negatively interact with biological tissues, making it an ideal material for surgical implants, dental prosthetics, and other biomedical devices. The process also enhances the lubricity of the surface, reducing friction and wear in moving parts, which is beneficial for applications in the automotive and aerospace industries.

The applications of nitrided titanium alloys are diverse and span across multiple industries. In aerospace, nitrided titanium components are used in aircraft engines, landing gear, and structural parts due to their high strength-to-weight ratio and resistance to extreme temperatures. In the medical field, nitrided titanium is employed in orthopedic implants, such as hip and knee replacements, due to its excellent biocompatibility and durability. Automotive components, including engine parts and exhaust systems, also benefit from nitriding treatment, as it improves their performance and longevity.

In conclusion, the nitriding treatment of titanium alloys is a sophisticated process that significantly enhances the surface properties of these materials. By incorporating nitrogen into the alloy’s surface, nitriding treatment results in the formation of a hard, wear-resistant nitride layer. This process offers numerous benefits, including improved hardness, wear resistance, fatigue strength, and biocompatibility, making nitrided titanium alloys suitable for a wide range of applications in industries such as aerospace, medical implants, and automotive components. The versatility and effectiveness of nitriding treatment underscore its importance in the advancement of titanium alloy technology.