Description

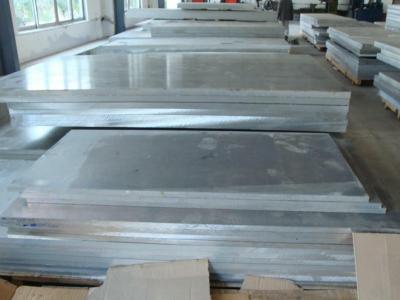

Étendue de la fourniture du groupe Aviation :

Il peut être personnalisé hors norme, plaque d'aluminium (plaque entière/coupe), tige d'aluminium, pièces forgées en aluminium, tubes d'aluminium, profils d'aluminium, etc. N'hésitez pas à vous renseigner !

1. Introduction à la 2A12 Matériaux

2A12 aluminum alloy Al-Cu-Mg aluminum alloy, main features and application range: This is a hard aluminum, which can be strengthened by heat treatment. It has medium plasticity in quenching and rigid quenching states, good spot welding, and tends to form intergranular cracks when using gas welding. The alloy has good cutting performance after quenching and cold hardening, and has low machinability after annealing: low corrosion resistance, and often uses male oxidation treatment and paint coating methods or an aluminum coated layer on the surface to improve its corrosion resistance.

Standard: GB/T 3191-2010 Replaces old GB/T 3191-1998

2. 2A12 composition chimique

| Médaille en alliage | Fer Fe | Cuivre Cu | Manganèse Mn | Magnésium Mg | Zinc Zn | Titane Ti | Nickel Ni | autres | Aluminium AL | ||

| Nouveau grade | Ancienne marque | 0.50 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.30 | 0.15 | 0.10 | Chaque | total | |

| 2A12 | LY12 | 0.05 | 0.10 | marge | |||||||

3. 2A12 mechanical properties and status

| Nuance et état de l'alliage d'aluminium | résistance à la traction

Rm/Mpa |

Rendement du rendement

Rp0,2/Mpa |

Élongation/% | Dureté/HBWα | densité

(20℃) (g/cm3) |

| 2A12-T4 | 425 | 275 | 12 | 120 | 2.8 |

The status of 2A12 is: T4, T3, T351, T451, H112

IV. 2A12 application fields

- 2A12 aluminum is mainly used for machine appearance parts structure, molds, transportation vehicles, compressors, rivets, truck hubs, spiral components and various other structural parts.

- It is mainly used to make various high-load parts and components (but not stamping forgings) such as skeleton parts on aircraft, skins, partitions, ribs, spars, rivets, etc., working parts below 150℃.