Optimizing High-Precision Wide-Width High-Temperature Alloy Strip for Enhanced Performance

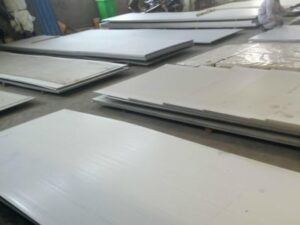

The development of high-temperature alloy strips has been a crucial aspect of various industrial applications due to their excellent heat resistance, mechanical strength, and oxidation resistance. Among these applications, high-precision wide-width high-temperature alloy strips have been gaining significant attention due to their unique properties that enable them to withstand extreme conditions. In this article, we will explore the optimization of these alloy strips for enhanced performance.

To optimize the performance of high-precision wide-width high-temperature alloy strips, several key factors must be considered during the production process. These factors include material selection, manufacturing techniques, and heat treatment processes.

Firstly, the selection of raw materials plays a crucial role in determining the properties of the final product. High-precision wide-width high-temperature alloy strips are typically made from alloys such as nickel, chromium, and molybdenum. The precise composition of these alloys is essential to achieve the desired properties, such as high-temperature strength and oxidation resistance. Careful selection of the raw materials ensures that the alloy strip can withstand the demanding conditions of industrial applications.

Secondly, the manufacturing techniques employed in producing high-precision wide-width high-temperature alloy strips significantly impact their performance. One of the critical manufacturing techniques is rolling, which involves passing the raw material between rollers to reduce its thickness. During the rolling process, it is essential to maintain strict control over the temperature, pressure, and speed to ensure uniformity in the alloy strip’s thickness and properties. Advanced rolling techniques, such as controlled rolling and direct rolling, can further enhance the precision and quality of the alloy strips.

Another critical factor in optimizing the performance of high-precision wide-width high-temperature alloy strips is the heat treatment process. Heat treatment is a process used to alter the physical and mechanical properties of the material by heating and cooling it in a controlled manner. The most common heat treatment processes for high-temperature alloys include solution heat treatment, aging, and precipitation hardening.

Solution heat treatment involves heating the alloy strip to a high temperature to dissolve the solutes and then quenching it to achieve a supersaturated solid solution. This process improves the alloy strip’s strength and hardness. Aging, on the other hand, involves reheating the alloy strip after quenching to allow the solutes to precipitate and stabilize the microstructure. This process enhances the alloy strip’s toughness and ductility.

Additionally, precipitation hardening is another important heat treatment process that can significantly improve the performance of high-precision wide-width high-temperature alloy strips. This process involves heating the alloy strip to a specific temperature, holding it for a certain duration, and then quenching it rapidly. This process promotes the formation of fine precipitates, which contribute to increased strength and hardness.

In conclusion, optimizing the performance of high-precision wide-width high-temperature alloy strips is a complex process that requires careful consideration of material selection, manufacturing techniques, and heat treatment processes. By focusing on these factors, manufacturers can produce alloy strips with superior properties, enabling them to withstand extreme conditions and meet the demands of various industrial applications. As technology continues to advance, the optimization of high-precision wide-width high-temperature alloy strips will play a vital role in the development of innovative solutions for a wide range of industries.